Rate website

Rate website

Rate website

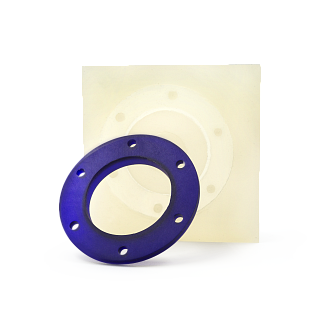

Silicone-Compatible Model

Description

Designed for master models printing. Could be used for making flexible molds from silicone on platinum or tin catalysts. The combination of high physical and mechanical characteristics and compatibility to silicones makes it possible to obtain high-quality silicone molds for their further use in jewelry and engineering. Low odor and the absence of harmful monomers allows you to work with it even in a small workshop.

Characteristics

- Colored liquid Appearance

- Violet Color

- 16 ± 2 % Elongation at break

- 92 ± 5 Hardness Shore D

- Weak Odor

- 550±300 mPa*s Viscosity according to Brookfield

- 1100 ± 100 MPa Flexural modulus of elasticity

- 900 ± 100 MPa Tensile modulus of elasticity

Benefits

Compitable with platinumcatalyzed silicone

The material has chemical inertness to silicones. It allows you to cast high quality silicone forms.

Low shrinkage

Shrinkage less than 0.5% gives you the same size like 3D model on your computer and it doesn’t change size after postcuring

Durable

Pigments and fillers are well stabilized, no sedimentation and flocculation occur ang no foam appears

Odorless

Resins are odorless and cause no irritation, so you can work with natural ventilation without special technique