Rate website

Rate website

Rate website

How to use HARZ Labs test?

Modern LCD and DLP printers allow you to print with great accuracy and speed, but to get good results you need to get the print settings right, whether it's the exposure time or the light-off delay.

To make this task easier, we have made our exposure test.

How to work with test?

The test can be downloaded from our website in the printer settings section, or by following this link:

https://harzlabs.com/upload/HARZlabs_Test.stl

Overview of the test

The first thing to do before you start printing a test is to set the initial settings on your printer. To simplify this task, we publish the basic printing settings on our website. You can use these settings as a starting point. After the settings are set, it is necessary to place the test on the platform. It is recommended to print the test directly from the build plate and without supports.

First, it is worth paying attention to whether the test has remained on the build platform. If the model did not stick to the build platform and remained on the film, the first thing to do is to repeat the calibration in full accordance with the printer manufacturer's instructions. If this does not work, and the re-test also remains on the film, it is recommended to increase the exposure time of the first layers, this will allow good adhesion to the build platform and the printing will be successful.

After the test is printed, it should be thoroughly washed and the following geometric elements should inspect.

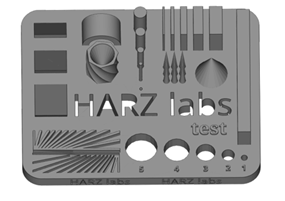

Configuration of the test elements

You should pay attention to the vertical columns (number 1) and vertical walls (number 2). They must be present on the dough and stand vertically, without slanting. If the small elements on the dough are not printed or the vertical walls start to bend, it is necessary to increase the exposure time. And if the material starts to polymerize between the walls, the exposure time should be decreased.

A useful tool on the test is the divergent lines (number 3). The lines should be well printed and should not merge. In case the lines start to merge, you need to reduce the exposure time, and may also be the result of insufficient pause before starting the exposure.

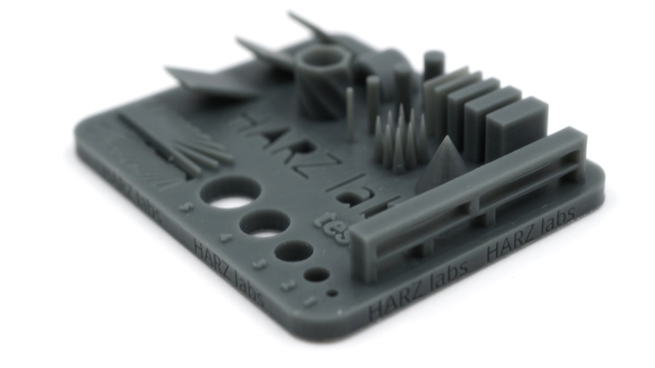

Test with too much exposure time

You must also pay attention to the horizontal bridge. There should not be any sagging layers on it. Such an effect occurs when the normal layers are insufficiently curing, which can further affect the deformation of the models and their collapse in the printing process subsequently.

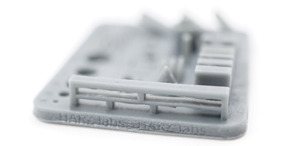

Configuration of the test, side view

With a smaller layer thickness (25 microns) and when working with soft and transparent resins, some sagging or merge is quite acceptable, and in this case, it is not recommended to greatly increase the exposure time.

Test with insufficient exposure time

In order to find the right pause before starting the exposure, it is necessary to look at the side lettering on the test. It should be clearly visible and readable.

Test with a small pause before the start of exposure

Base layers of the model are cured stronger than the normal layers and there is a parasitic curing in the XY plane, so "elephant foot" is acceptable. That provides a good adhesion between the model and the printing platform. If this "elephant foot" is too large and it turns into thin films around the model, then it makes sense to reduce the exposure time of the first layers.

Test with too much base exposure

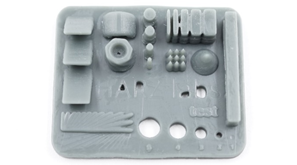

For illustration, here is an example of a good test below. Printed with HARZ Labs Model Grey resin on an Asiga Max UV printer.

HARZ Labs Test