Rate website

Rate website

Rate website

Recommendations for the use of Dental Sand PRO and Dental Bleach PRO

Dental Sand PRO and Dental Bleach PRO are ceramic-filled resins for printing long-term temporary crown and bridge models. Due to low moisture absorption and balanced micro ceramic-filling, this resin makes it possible to produce models with long service life and durability. Printed crown and bridge models are polished well and can be customized using composite stains. A slight odor and the absence of harmful monomers allow you to work even in a small room. Meets the requirements of ISO 10993.

General recommendations

Depending on the used equipment, the cement gap can vary from 60 to 120 microns. We recommend choosing the optimal gap by fitting the model.

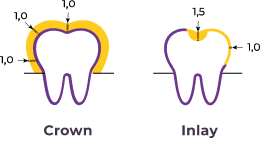

The minimum recommended wall thickness, mm

In case of failed printing (partially or completely unprinted model, polymerized particles in the vat on the film of the 3D printer), filter the photopolymer through a 190 micron paint strainer.

The use of 3D printers equipped with an uncoated aluminum platform can lead to a change in the shade of the printing models due to the abrasive properties of the ceramics in the composition of the material. In such cases, install additional platform protection recommended by the 3D printer manufacturer. It can be a magnetic plate, frosted glass, or an anodized version of the platform.

Printing

HARZ Labs Dental Sand PRO and Dental Bleach PRO have been tested and validated on various 3D printers and post-processing devices. We are continuously working on the validation of the actual equipment. The list of compatible devices is indicated in the post-processing table on our website harzlabs.com in the Support section.

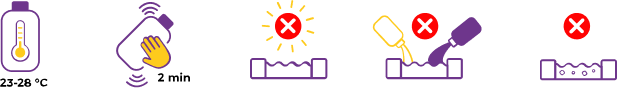

Filling the 3D printer vat

Before printing, make sure that the resin temperature is between 23-28°C. Shake the bottle well for at least 2 minutes. The material must be opaque and have a uniform consistency. Pour the resin into the 3D printer vat according to the level. Do not mix the resin with different batches. Prevent foreign particles from entering the resin. Keep the resin away from light.

Settings

The starting settings for your 3D printer are listed on the website in the technical support section. Follow the 3D printer's instruction manual and equipment manufacturer's recommendations. Before printing models, be sure to print a calibration test and make sure that the parameters are selected correctly. To adjust the settings, refer to the calibration test manual.

Removing printed parts from the platform

After the printing process is completed, separate the printed objects from the working platform of the printer by using a suitable instrument (e.g. spatula or stationery knife). Use protective goggles and gloves.

Cleaning printed parts, step 1

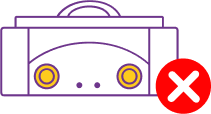

Clean printed objects for 3 minutes in ethyl or isopropyl alcohol ( 96%) to remove excess resin from the model surface. Use an ultrasonic bath (without heating) or hand wash with a synthetic brush soaked in alcohol.

Cleaning printed parts, step 2

Clean printed objects in pure ethyl or isopropyl alcohol ( 96%) for an additional 3 minutes using an unheated ultrasonic bath. Visually verify the quality of the washing there should be no liquid resin on the surface and inside.

Precautions

The total cleaning time in ethanol or isopropyl alcohol should not exceed 6 minutes, as this may cause defects in the printed models.

After cleaning, dry the printed model with compressed air. If liquid resin remains on the model surface, it can be completely removed by spraying with ethyl or isopropyl alcohol ( 96%) and blowing again.

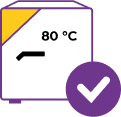

Models heating

After cleaning and blowing with compressed air, place the printed object in a heating chamber at 80°C for 10 minutes. Heating is necessary for removing internal stresses inside the models, evaporating alcohol from the surface of the model, as well as partial UV-curing.

Avoid models' overheating! Do not use devices without precise temperature control (household appliances, nail sterilizers, etc.)

Supports removing

Supports can be removed after washing or after heating. Removing supports after heating will reduce the risk of craters from contact points on the model surface. Supports can be removed either manually or with a hand tool.

Post-Curing

For the final polymerization, it is necessary to use a UV-light curing box. Upon completion, the object is allowed to cool for 3-5 minutes until it feels cool to the touch.

We strongly recommend using the Otoflash G171.

To obtain the declared properties and the required color, use the next recommendations.

Device

Otoflash G171

Curing

3000 flashes

HARZ Labs Dental Sand PRO and Denlat Bleach PRO have been tested and validated in combination with several post-curing devices. An additional list of compatible devices can be found in the post-processing section.

WARNING! Only HARZ Labs approved equipment may be used. It is mandatory to follow all stages of product processing. Otherwise, there is a high risk of obtaining unreliable and/or unusable dental products that may compromise patient safety.

Note: The data on settings, processing, and warming up are applicable only on regularly maintained and calibrated devices that ensure proper stability of light intensity and spectrum, temperature, etc.

Finishing

Fully post-processed models can be finished using conventional dental instruments. Polish to a high gloss using polishing brushes, discs, or silicone polishers. Avoid overheating of models during finishing and polishing.